A School Divided: Uniting Three Brands with One Solution

Client:

Trona Unified School District

Materials/Products & Services:

Window Perf, 6mm Aluminum Composite, Vinyl Cut Letters, Anti-Graffiti Lamination, Graphic Design, and Installation

Project:

Creating three different branded entrances within a single site for an Elementary, High School, and School District

This project took us to the far reaches of the Mohave Desert. We didn’t know precisely where Trona Unified School District was until we realized it was a part of the desert commonly known as Death Valley. The Searles Lake is a “terminal” lake in the Searles Valley in the northwestern part of San Bernardino County. Some people might even know this as Borax Lake. The mining community of Trona is on its western shore and yields approximately 1.7 million tons of industrial minerals annually.

Several billion tons of mineral deposits lay beneath the flat lakebed, in fact, an entire periodic table of minerals and salts. Searles Lake contains samples of half the natural elements known to humanity. The lake was discovered in 1862 by Dennis and John Searles, who happened to be searching for gold in the area. Later they met “The Borax King” Francis Marion Smith and launched mineral extraction operations from the lake’s deposits. The best occasion to visit Searles Lake is during the annual Gem-O-Rama geological event every second weekend of October.

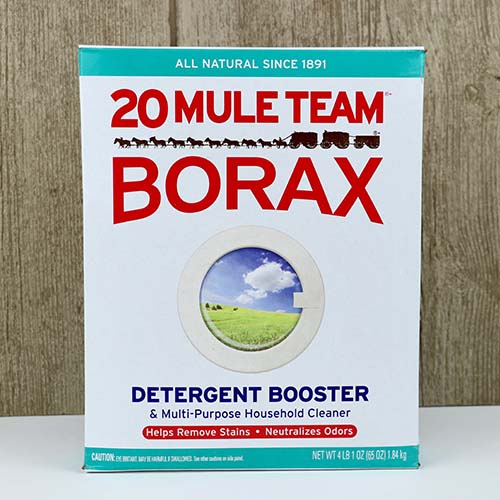

Speaking of Borax, you may remember the iconic 20 Mule Team on the front of the soapbox and the television commercials done by Ronald Reagan during the series “Death Valley Days” from 1964-1965. He was the host of “Death Valley Days” a series on television. Our former 40th President acted in some episodes before his political aspirations took him away from Hollywood. Pacific Coast Borax Company sponsored the program, which later became U.S. Borax.

Appreciating the History of Borax

The Borax twenty-mule team is one of the most memorable icons of the American West and the pioneers. They transformed their mineral wealth into the foundation of the modern industry worldwide. Today that twenty-mule team is the proud symbol of a visionary company that remains the global supplier of choice for customers seeking outstanding products, value, and service.

The use of borax dates back to ancient times. The Egyptians used it for mummification, and in the late 1800’s Boron compounds were a household staple. It was known as the “miracle mineral” used as a medicine, food additive, and cleaner.

U.S. Borax traces its origins to Death Valley, where the first Borate Deposits were discovered in 1812. The first 20 mule team hauled Borax 165 miles through Death Valley in scorching heat in 1883. Fully loaded with two ore wagons and a 1,200-gallon water wagon, the rig weighed 36.5 tons. A 20-mule team consisted of 18 mules, and two draft horses hitched closest to the wagon to ensure a steady pull. In Mohave, wagons were constructed for $900 each, designed for balance and strength as well as carrying a heavy load of borax ore. Each wagon was capable of carrying ten tons (about one-tenth the weight of a modern railroad freight car). Empty, each wagon still weighed 7,800lbs.

The one-way trip from the mine to the railroad took ten days across the desert and mountains. Water from two natural springs bubbled along the route, and in some instances, it was piped down into wells. When the distance between the wells was too far, the teams relied on the water wagon they carried behind them. In the sweltering heat, wooden tanks tended to dry out and fall apart, so heavy iron tanks were used.

The first two mules in the twenty-mule train were chosen based on their intelligence and ability to lead the others. The next ten were called the “swing team” worker mules that did not require special training except to respond to commands. Followed by the “pointers,” these mules were specially trained to leap over the chain when the team turned a corner. Finally, the “wheelers” were the last part of the team. These mules or sometimes draft horses were the largest and strongest of the pack animals.

On top of the wagon were the drivers called “muleskinners.” They served as trainers, drivers, veterinarians, and mechanics, usually solitary men who had short tempers and were used to enduring extreme hardships. For their efforts, muleskinners earned $100 to $120 per month, very high wages for that time in history. Between 1883 and 1889, the twenty-mule teams hauled more than 20 million pounds of borax ore out of the Valley. Not a single animal nor a wagon broke down during this time. The ingenuity of the builders and designers and the perseverance of the men and mules prevailed.

After diligently hauling borax out of the Valley for more than five years, the twenty-mule teams were relieved of their daunting task by the growth of the railroad. Today, it would take more than 250 mule teams to transport the borax ore processed in just one day at Borax’s modern facility in the Mohave Desert. Not surprisingly, this mine supplies more than half of the world’s borax needs.

Long after they ceased to make the torturous trek from Death Valley, the teams continued to make many promotional and ceremonial appearances on behalf of the U.S. Borax Company. Today, borax is not recommended for medicinal use like a century ago. However, boric acid, borax, and boron compounds are utilized in almost every major industry. Some examples are the making of fiberglass, Pyrex, laboratory glassware, ceramics, porcelain enamel, detergents and soaps, aircraft and automobile anti-freeze, brake fluid, cosmetics, building materials, flame retardants, and electronics. It truly is nature’s miracle mineral.

How to Unite Three Brands Under One Structure with Signage

After the Magnitude 6.4 earthquake on July 4, 2019, and the Magnitude 7.1 earthquake two days later in Searles Valley, the Trona High School and Trona Unified School District offices were deemed unsafe for occupancy. The school district explored their options and determined it was best to consolidate all operations at the elementary school site. After completing the required construction, the site was ready for use. However, because it was now a multi-purpose school, the district needed to clearly identify the Elementary School from the High School and the District offices. A&I was called upon to help transform each school into its own unique identity and identifiable entrance. Additionally, creating a branded signage entrance for the district office location.

The A&I team printed each school graphic and logo onto perforated window film and installed it on windows surrounding the three main entrances separating each individual site. It was also used to identify the Trona Unified District Office and the Elementary School Office location.

Window Perf (perforated window vinyl film)

Window Perf is an adhesive-backed, perforated synthetic substrate with full-color printing on one side. It allows your printed message to be seen from the outside while still allowing you to see through from the inside. Made with hundreds of tiny holes, it looks like a screen when you look from the inside out. It is perfect for keeping the sun out, and your cooling costs down. You can use it on architectural glass and side or rear automotive windows. Window Perf comes in a range of sizes from 1′ x 1′ to 150′ by 53″ (inches) and can be laminated. If using Window Perf in a dusty area or on automobile windows, we highly recommend lamination to keep dirt out of the holes.

Aluminum Composite (ACM) Material

Next, A&I needed to print signs. Aluminum Composite (ACM) material was used on the block wall at the main entrance to the site. In conjunction with the High School Logo, text identifies which building high school students should use to attend classes. The artwork was printed directly on the 6mm ACM and then protected and enhanced with an anti-graffiti lamination. To create a free-standing sign outside the gates of the multi-purpose site, we used solid aluminum material with vinyl cut lettering and an overprotective laminate. This sign identified the new location of the district office. Concrete footings were cut through existing asphalt paving outside the main gate to give the sign greater durability against wind and desert elements.

Aluminum Composite Material consists of two .15mm aluminum panels bonded to a solid polyethylene core, just like a sandwich. It is lighter and more durable than regular aluminum signage or MDO (medium density overlay-specialty plywood). It resists scratching, and the finish is ready for vinyl, screen print inks, paint, cutting, or routing. ACM is your best choice for outside signage exposed to harsh environments at a much more reasonable cost than so many other substrates. Maxmetal is our product of choice on this project due to its print quality and durability.

Anti-Graffiti Lamination: Extra Protection

Anti-Graffiti Lamination is truly something everyone should use. There are different brands out there, and they all have protection from 3 years to 7 years. We chose to use Grimco’s “Vandal Guard.” This excellent protectant is pressure sealed over your signage and protects against spray paint, permanent markers, crayons, etc. When the sign has been marked on, you simply wipe it off with a rag and lacquer thinner. The company’s video touted that you could wipe a sign down 200 times and never damage the laminate. It was so impressive to watch and clearly would save anyone from reprinting or replacing vandalized signage.

There are so many beautiful choices for signage available now, and with protection, signs can last for many years, even exposed to the harshest elements and environments. A&I can fabricate and print signage for any building, budget, and occasion.